Ski testing:

Ski testing is possible upon request. A service fee of CZK 300 is charged and the easiest place to pick up skis is in Prague, however other vicinities may be agreed upon individually.

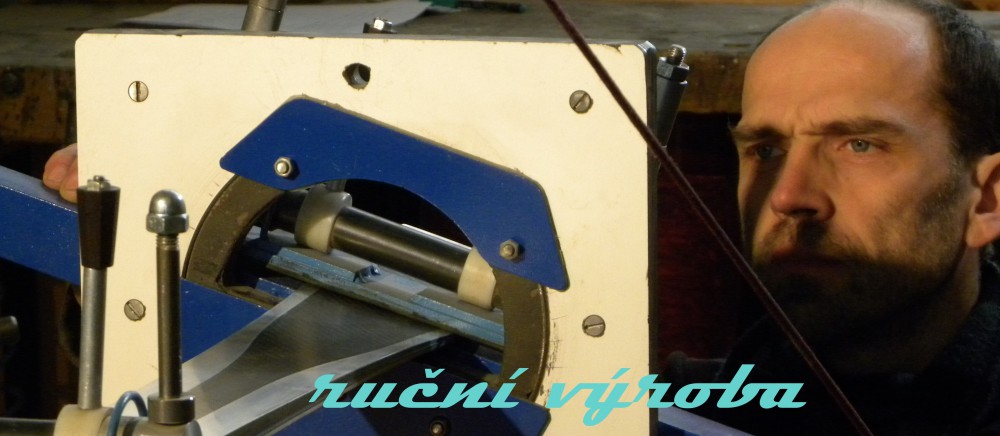

By visiting our production facility, we demonstrate how exactly our unique skis are made and from which materials.

The primary vision was to produce top quality skis and later on we discovered that we can make impressive skis for an affordable price. We then initiated sales. Currently, the quality of sport equipment significantly influences the skier's performance. Using the latest technology, we manage to save up to 1 kg per a pair of such skis.

During the 2010/2011 season, we succeeded in developing our slalom skis 165 cm long with a radius of 14 meters and then women's sport skis 162 cm.

In 2011/2012, faster 172 cm and 165 cm skis for very ambitious skiers were added in our product line.

This year, we have combined a collection of 155cm, 165cm and 172cm from these models.

We have learned a lot during production development and with each new ski we continue to innovate.

During the summer of 2012, we created a distinctive design for our skis, thus further enhancing their exclusivity.

Price for a pair of Carbon skis is from CZK 29 900,-

The best technology in elegant design. Skis that will be your support on icy ski slopes and also in a society.

follow us

follow us